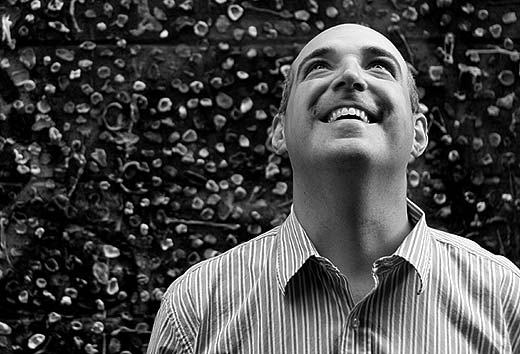

Co-founder and vice president of Motawi Tileworks, Karim Motawi is half of a brother-sister team that turned their custom tile garage startup into a $2 million business.

Selected as one of Crain's Detroit Business 2006 "

40 Under 40," Karim is an entrepeneur and innovator. He keeps active in the Ann Arbor community and sits on the board of the Ann Arbor Art Center.

Join the conversation with your comments!

Photograph by Ryan Hoover - All Rights Reserved

THIS BLOG FIRST APPEARED IN

METROMODE

Posted By: Karim Motawi

Posted: 8/29/2007

He who has the best brand wins.

Everybody knows how important a strong brand is for larger companies--think Pepsi and Coke. But I’ve come to believe that a strong brand is even more important for smaller companies.

With the advent of Internet marketing and cheap shipping, even small manufacturers are facing national and even global competition. A small good company with a local client base now has to compete with many other small and some times giant companies. Who will win out as even small companies across the country are literally forced to compete with all comers?

Other factors being equal, price, quality and service the company with the better brand, even if it is a small brand will be the winner.

In our own small industry of handmade tile, we have seen a growing awareness of the importance of a strong brand.

In the past, and in some cases even now, tile retailers literally disguise the brand name of a product. They do this to keep customers from trying to source the same tile from another retailer at a better price. As a manufacturer we didn’t like it, but we lived with it as we figured we would get the sale in the end.

But now, as even the art tile market is being flooded with imported look-a-like products, the use and defense of our brand has become a serious issue. We are working hard to maintain our brand and encourage our retailers to join us in supporting it. A good brand, and a good product, will command a higher price, and who doesn’t like that?

So think about your brand and if you don’t have one, make a good one.

Posted By: Karim Motawi

Posted: 8/28/2007

What are you bringing to the party? As we at Motawi have enjoyed some modest success over the past few years, I've met several people who want to get into the art tile business. They ask me "What made you think you could do it?" The truth is we didn't think about that when we started. We started young, in our early twenties, and my sister and I didn't really think about how we would do it. NaivetÇ played a big role in our beginning. I think I have a better understanding now, 15 years on, as to how we did it. Now, the first thing I ask a person who wants to start a art tile business, but I figure it applies to any new small manufacturing business, is "What are you bringing to the party?"

The existing companies in any established market have several advantages. They have an experienced production staff, distribution, marketing and knowledge of the market. A new player must overcome these advantages to build a success. So, what is so special about what you are doing that people will buy your product instead of the other guy's? And will you be able to keep developing new products that are special enough? "What are you bringing to the party?" Is your design better? Is your manufacturing process better? Something has go to be better. The desire to succeed is not enough. As a small player in a market being just as good as the other guy is not enough. You have to be better.

Posted By: Karim Motawi

Posted: 8/27/2007

Small can be beautiful, even in business. I've been having a lot of chats with my soon to be unemployed neighbor who works at Pfizer here in Ann Arbor. We talk about what he is going to do next and what his co-workers are doing. I have to tell you, he surprised me. He is genuinely excited and not just about his prospects, he is excited about the prospects of the region. Huh? To him, and I believe it now, too, the loss of Pfizer will be a net benefit to Ann Arbor. Pfizer was a dandelion that has just been kicked by a child. The seeds, it's employees, have been cast to the winds to start...you guessed it, more life science companies.

These new companies are going to be just the right size, small. Why is small better? People who start small companies are the most highly motivated people in business. They have just put everything on the line for something they believe in. You don't start a business on a whim, you start it because you believe fervently that you can make a success of it. My neighbor tells me his co-workers are ready to go. For years they have let opportunities for new research and ideas for startup companies go by as they enjoyed the golden handcuffs of safe and secure well paying jobs. The cuffs are off. I'm looking forward to seeing what happens to the starts ups that are being developed by former Pfizer people. These little companies led by motivated bright people recently freed from a large bureaucracy are going to do some good work. And I'm betting they will be doing it right here in Ann Arbor.

Posted By: Karim Motawi

Posted: 8/24/2007

Lean Manufacturing for the little guy

Our art tile company had grown strongly for 7 years, but a faltering economy and 9/11 caused a slowdown for us. The sins that had been disguised by very rapid growth appeared and we knew we needed to do something or our company would fail. The 'something' we found was lean manufacturing. In it's simplest terms, lean manufacturing is the practice of constantly improving the processes one uses to manufacture a product. If one focuses on improving the processes used to make a product you will develop a great process. A 'side effect' of this great process will be a great product.

I know it sounds strange, but I'm here to tell you it can work, even for a small art-driven company like ours. One of the cornerstones of the lean manufacturing process is the identification and reduction of the "Seven Wastes." Once you learn to identify them and counter them you are on your way to cleaning up your processes.

The Seven Wastes:

- Unnecessary transport of materials

- Inventories

- Motions of employees

- Waiting for the next process step

- Overproduction ahead of demand

- Overprocessing of parts

- Producing Defective parts

As we've leaned about theses systems at Motawi, we have come to believe that lean manufacturing principles can be applied to a company of any size, even to a one man shop. While the people who have done the most work on this subject have worked within large companies, I am convinced that the ideals of lean manufacturing can bring equally positive results for small companies. For us it has meant lower inventories, lower defect rates, lower lead times and higher profits. What more could you ask for? For more information on Lean Manufacturing, just Google it and you will find years worth of reading.

Posted By: Karim Motawi

Posted: 8/23/2007

It's ok to ask for help. As a group we small business owners can be an independent lot, sometimes too independent. We like to do our own thing and think we know best, which is half the reason we are small business owners in the first place. Within our companies we are often seen as the guy with all the answers, the buck does stop here after all. Well, I have found that folks like us sometimes have a hard time admitting we are in over our head. We can't be the guy with all the answers all the time, even if we want to be. So being able to ask for help is an important skill.

I have found that asking for help has helped our company greatly. The time was July 2001, just before 9/11. We had just moved into a new building and were a little house poor and the economy was slumping . Then 9/11 happened. We were in trouble. We had no formal training in how to organize a manufacturing system and we were on the ropes. I went looking for a solution to our woes and while reading a book on lean manufacturing came across Jeffrey Liker, a U of M professor and an expert in the field. I asked for help.

What I ended up getting was a Ph.D candidate who was looking for a case study on how to apply lean manufacturing systems to small companies. Bingo! We ended up spending 3 hours a week for the next three years with our new friend implementing a Toyota style system in our studio. We got in over our heads, we swallowed our pride, and asked for help. I highly recommend it.